There's much more to Performance Plastics than injection moulding.

Quality Experience Automation Statistical process control Part decoration Additive manufacturing Ultrasonic welding Assembly services Machine vision Reporting ISO 9001:2015 Equipment Efficiency Mould Flow Warehouse management software Design Value Integrityabove all else.

Drive growth by choosing a manufacturing partner with

all the right technologies.

Choose a partner that's close to your customers.

Over 50 million people, and countless businesses

located within our commercial driving window.

From PLA to reinforced nylon. Prototypes to production.

Near limitless 3D printing.In house.

Modern engineering resins can satisfy 95% of application requirements.

We use advanced additives to satisfy the remaining 5%.

Production & Quality

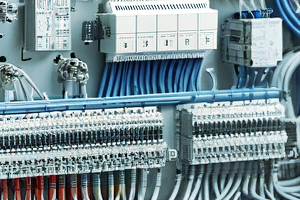

Broad Implementation of Production and Quality Technologies

It's one of the things that sets us apart.

From the software that schedules work orders, to the hardware that captures their progress in real time. From the systems that manage inventory, to the equipment that's responsible for consuming it. And from the system that defines and schedules quality inspections, to the tools used to perform them.

Real-Time Production Monitoring

To round out the system, comprehensive computer kiosks are installed at every press, and provide all the tools our employees need to take full advantage of the real time production technology. If you're interested in learning more about this exciting technology, please give us a call at (416) 292-7765. Warehouse Management System (WMS)

Performance Plastics Limited's WMS is an integral part of our manufacturing operation. It provides full visibility of inventory items at every step of the journey they take through our facility. From the moment a product enters our facility and through it's conversion into a finished good, we know where it is, how much of it we have, and where it's going. All-Electric and Hybrid Molding Machines

These machines are accurate, energy efficient, and cycle fast. Their reduced operating costs and improved production rates ensure we can compete with anyone. If you have a job you would like us to look at, please let us know. Gravimetric Additive Dosing

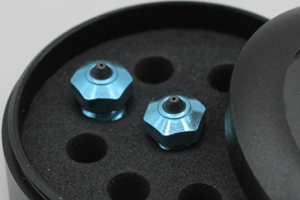

We achieve a high degree of precision in dosing primarily through the use of machine mounted gravimetric feeders. These units are tied directly into the machine, weigh every dose of additive to within 0.01g, and introduce it directly into the material stream. These units are also adept at handling traditional colour masterbatches. Consistency in colour from run to run is easily achievable, and the tightly controlled dosing allows us to utilize colours formulated for very low let down ratios. We have successfully run transparent colours as low as 1:500, and can reliably run many specially formulated colours at 1:100. Machine Vision

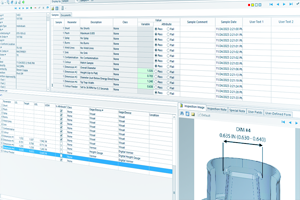

In the quality lab, the high resolution cameras and powerful processing unit can measure a part, or check for flash, shorts and other visible defects. On the shop floor, we can use machine vision to verify production processes at the press level. Ensuring shots are complete, inserts are present during over-moulding operations, and operators can perform critical quality checks at the source. Inspection Automation and Reporting

First-off and in-process quality inspections are an integral part of every quality plan. We believe that how a company controls its inspections is as important as the inspections themselves. All our inspections are developed, implemented, completed, and reported on by automated quality assurance software. While there are too many to list here, some of the key features of the technology include:

If you want to learn more about our quality system, we've dedicated a whole page to it. Better yet, you can arrange a visit, and see how it operates in-person. End to End Product TraceabilityEvery serial number tells a story…  Provide us with one from any finished good container, and we can pull the lot numbers of the resin and components that were used in its manufacture. We can also tell you who ordered the materials, who received them and when, who inspected them, what else they were used to produce, and provide a copy of the manufacturer’s certifications. Need more information on the parts? We can tell you what cycle the machine was running when they were packed, share any downtime notes for the shift, tell you which operator packed the part, and provide a record of their training. Need that information fast? We can provide all of it in minutes - all from a single number. We take our commitment to traceability seriously, and our customers love the peace of mind it offers. |

Development & Support

Development Services to Support our Customers

All done in-house.

Engage with a partner that's equipped with a full suite of advanced technologies to support your initiatives. Decades of experience designing and validating parts for injection moulding allows us to fully leverage them on your behalf.

Learn more about the development technologies Performance Plastics offers below:

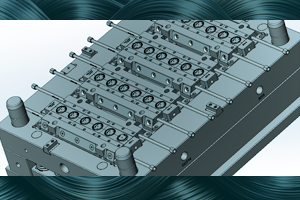

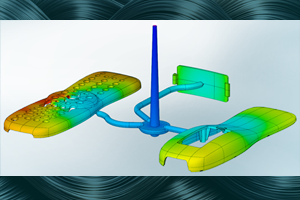

Multi-Material 3D PrintingTo support our customers through the entire lifecycle of their projects, we offer in-house access to a robust, commercial 3D printing solution.  While the system excels at short-run production, it's also valuable as a development tool. The dual, high temperature extruders paired with diamond nozzle tips allow us to build parts in almost any commercially available filament. In many cases we can combine multiple materials in the same build, or even the same part. Ultimately, we can build functional prototypes in the same resins as your production parts. If you would like more information on our 3D printing service, or would like to request a sample, please contact us. Please note: We don't take chances with your intellectual property. Our commercial printer is operated on a private, air-gapped network. 3D Modelling Our professional CAD suites are primarily used to facilitate collaboration between us, our customers, and our vendors. With everything running on powerful ISV workstations, we get up to speed quickly, rendering and generating error-free files. Regardless of your preferred software, we can work with your team. Smaller customers, or those with finite engineering resources can task us with engineering changes and refinements, or full part design. We are well-equipped to contribute at any stage of development. All design activities are fully controlled, and covered by our ISO certification. Comprehensive Mould Flow Analysis We perform a comprehensive mould flow analysis on every tool we commission as part of the design approval process. The advanced software provides valuable insights into a tool's expected performance, while identifying areas of concern and informing approaches to address them Among other things, we use the results of the analysis to optimize the part's design, identify ideal gate size and location, and enhance cooling efficiency. Doing so reduces the risk of costly re-work during later stages of development. We believe this service benefits us just as much as our customers, and for that reason we provide it at no additional cost. |

Management

Customer Service and Planning Tools

Front office technologies to keep things running smoothly.

Seamless integration between front office and factory floor technologies ensures accurate scheduling, resource allocation, and allows us to respond immediately and with confidence to customer requests.